Devices and Methods for Microclimate Research in Closed Areas – Underground Mining

Volume 6, Issue 4, Page No 395-400, 2021

Author’s Name: Mila Ilieva-Obretenovaa)

View Affiliations

Electrical Engineering Department, The University of Mining and Geology, “St. Ivan Rilski”, Studentski Grad, “prof. Boyan Kamenov” Street, Sofia 1700, Bulgaria

a)Author to whom correspondence should be addressed. E-mail: mila.ilieva@mgu.bg

Adv. Sci. Technol. Eng. Syst. J. 6(4), 395-400 (2021); ![]() DOI: 10.25046/aj060444

DOI: 10.25046/aj060444

Keywords: Sensors, Measurement Devices, Microcontroller, Data transfer, Underground Mining

Export Citations

Technical safety and health are especially important for mining-extracting industry. Even though the respective lows and good engineering practices exist, technologies develop and could address even better security for humans and equipment. The research question is to survey microclimate sensors in underground mining and to find whether they are ready for automation. The article is inspired from the research in “Computer System for Microclimate Management in Closed Areas of the Post-Mining Galleries and Greenhouses”. The author offers a short review of state and trends in development of sensors and devices for monitoring and reporting of environmental parameters in underground mining. All environmental parameters: air temperature; temperature of surrounding building constructions, heated surfaces of technological machines and equipment; heat flow, heat irradiation; relative humidity; velocity of air flow; noise; illumination; gas concentration; dust level; ionizing radiations; radon concentration in air are represented with relevant measurement devices and measurement units. The next step is representing of fast-developing sensors using scientific references. Author performs quality assessment of their suitability for automated data transfer and management. The assessment criteria are: Analogue measurement devices, Digital measurement devices, Availability of microcontroller. Findings are proposed for discussion: recent used devices in underground mining are not suitable for automatization, because they miss a controller. The availability of controller also presumes availability of management services. On the base of articles about management of sensors and controllers future work is proposed: 1. Integration of existing elements sensor and controller and defining of its management; 2. Moving of new elements and synthesis of algorithms for its management. This will lead to more precise assessment of industrial risk and improvement of safety activities.

Received: 29 April 2021, Accepted: 14 August 2021, Published Online: 28 August 2021

1. Introduction

Mining-extraction sector is especially important for the economics in Bulgaria. Therefore, the technical safety and professional health must embrace different activities on protection of employees and assets by reducing to minimum of dangers, hazards, failures, and oversights. Even though the respective lows and good engineering practices exist technologies develop and could address even better security of humans and equipment.

The article is inspired from research in [1] which considers a computer system for microclimate management in closed areas of post-mining galleries and greenhouses. Other authors describe this problem too. In [2], the authors represent Pictograms for admissible norms of harmful substances, but they miss devices and measurement methods. In [3], the organizers display a standard for microclimate design, but they miss details for modern devices for monitoring and reporting. In [4], the authors consider safety technics in underground mining, but without details in trends for devices and sensors. In [5], the author describes methods and devices of illumination technology in underground mining and tunnels, but without including other parameter of environment and the appropriate measurement devices. In [6] and [7], the authors represent rules for radioactivity (radon) measurement, while [8] portrays harmless work with cyanides, and [9] displays design of industrial ventilation, but they all miss automated data transfer. In [10], the authors describe a wireless permanent monitoring of coal strata, which could be applied to wireless permanent monitoring of microclimate. In [11], the author explains levels of IoT environment in underground mining as the emphasis is on the security of data transfer, but different sensor types and their management are not detailed.

The purpose of the article is to make a short review of state and trends of sensors and devices for monitoring and reporting of environmental parameters in underground mining and to accomplish a quality assessment of their suitability for automated data transfer and management.

2. Methodology

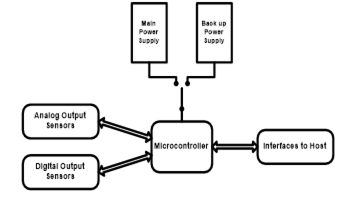

The survey of sensors for underground mining is accomplished in University of Mining and Geology, a leading university on mining science in Bulgaria. Author performs the research after publishing the guide on safety technics in underground mining sponsored [4]. All parameters of the closed area, basic sensors, and measurement units are represented. In the next step the fast-developing sensors with their improved versions are depicted. The author uses specialized references. Assessment criteria for measurement devices are defined on the base of Computer System for Microclimate Management in Closed Areas of the Post-Mining Galleries and Greenhouses [1]. Sensors have analogue or digital output in this system. This leads to the important need of placement of an analog-to-digital converter (ADC) and building of digital interface (SPI, I2C, CAN, Ethernet, etc.) [12], [13]. Most of the built-in ADCs have a resolution of 10 or 12 bits and contain 8-16 input channels which is sufficient for these applications [14]. The core of the system is a microcontroller that samples data from the sensors, processes the information and sends it to a computer through interfaces. Since this system will sample data during long periods of time (minutes, hours, days or even months), a backup power supply is needed along with the main one [15]. The switching between these two power supplies must happen automatically; therefore, an electronic switch is needed too. The results from the measurements should be transferred to the computer, where the end-user can view them. This is done with the interface RS232 [16]. As more than one system is used, the interface could be Wi-Fi to speed up the process of data gathering [17]. The network of measurement elements consists of a base microcomputer station and several sensors, distributed in the space, and linked to the station by cables or wireless Ethernet. The measurement of all climatic elements is made within 1 sec in total with an interval between the separate measurements – 3 minutes. It is necessary to perform measurements with low speed, as most of the values are not changing rapidly and because of the inertia of the sensors. Figure 1 shows the existing Computer System for Microclimate Management in Closed Areas of the Post-Mining Galleries and Greenhouses [1]. Cortex-M0 architecture is used. It has a 32-bit embedded microprocessor, especially designed for low-powered optimized microcontrollers.

Therefore, specialists could assess the new sensors by the following three criteria:

- Whether are they analogue?

- Whether are they digital?

- Whether are they connected to microcontroller for automated data transfer?

Figure 1: Computer system for microclimate management in closed areas of the post-mining galleries and greenhouses

Figure 1: Computer system for microclimate management in closed areas of the post-mining galleries and greenhouses

Next steps are:

- Discussion of findings and their consequences and

- Proposal of future work about devices` investigation.

3. Results

The first result from the survey represents the systemized environmental parameters in underground mining, conventional devices for their measurement and the corresponding measurement units. It is shown in Table 1.

Table 1: Environmental parameters in underground mining, conventional devices for their measurement and the corresponding measurement units

| Parameter | Device and measurement unit |

| 1. Air Temperature | Quicksilver and Thermistor Thermometers, [ºC] |

| 2.Temperature of surrounding building constructions, heated surfaces of technological machines and equipment. | Contact Thermometers, [ºC] |

| 3.Heat flow, Heat irradiation | Actinometer, [W/m2] |

| 4.Relative Humidity | Psychrometer of Assmann, [%] |

| 5.Velocity of air flow | Anemometer, Kata Thermometer, [m/s] |

| 6.Noise | Noise meter (Sound meter) for exposition; integrating noise meter; stationary installations; installations, fitted to human (dosimeters), [dB] |

| 7.Illumination | Luxmeter (Illuminance Meter), [lx]

Luminance Meter [cd/m2] Spectroradiometer, [nm] |

| 8.Gas concentration | Gas analyzer, [%] |

| 9.Dust level | Konimeter, [particles number/cm3] |

| 10.Ionizing radiations | Geiger-Muller counter, [Sv]

Scintillation counter, [Sv] Pocket chambers and Pocket Dosimeters, [Sv] Film badge Dosimeter, [Sv] Thermoluminescent Dosimeters (TLDs), [Sv] Electronic Personal Dosimeter (EPD), [Sv] |

| 11.Radon Concentration in Air | Hermetically closed chamber, [%] |

The second result from the survey shows the fast-developing sensors according to specialized references. These are sensors for air temperature, heat flow, relative humidity, illumination, and gas concentration.

3.1. Sensors for Air Temperature

Classical measurement devices for air temperature are quicksilver and thermistor [18] thermometers, but they miss automated data transfer.

In [19], the authors represent smart temperature sensors and systems of temperature sensors. For temperature measurements in smart sensors and microelectromechanical systems the most frequently used elements are transistors, thermocouples, and thermopiles (several connected thermocouples), because these elements could be accomplished with integrated circuits technology. For the temperature range from -55ºC to 150ºC bipolar transistors are especially useful as temperature sensors because they could be produced by practically all standard technologies for integrated circuits together with other circuits. With similar circuits could be made a reference for a voltage gap. This allows performing of radiometric research, where temperature sensing voltages are compared with predefined voltage reference. By CMOS analogue circuits extremely high precision could be achieved by using error-reducing technics such as dynamic synchronization of elements and chopping (signal cutting). The smart temperature sensor is represented with output signal with modulated duty cycle. High precision is reached with remarkable low energy consumption. The output of sensor is digital, but without automated data transfer.

In [20], the authors portray a temperature sensor with bipolar transistor used as a diode. Thereby bigger temperature range, lower power consumption and smaller chip area are reached. The sensor works in time mode: The time is measured for a capacitor charging to activating voltage of the transistor. A comparator is used instead of conventional sigma-delta analog-to-digital converter. Therefore, output of the sensor is digitized, but without automated data transfer.

3.2. Sensors for Heat Flow

In underground mining a heat flow is measured, coming from surrounding building constructions, heated surfaces of technological machines and equipment. Classical measurement instruments for heat flow are with thermistors (thermopiles) [21]. The sensor consists of a set of thermistors and an array of converters produces voltage, proportional of the heat flow and allows direct measurement of heat flow. The availability of thermistors array allows to be made a comparison between heat flow assessment, obtained from converters, and calculated heat flow, using temperature differences and Fourier Low. The element is extremely sensitive with accuracy lower than 0.1 heat flow units (HFU) and could be used for long term readings. The output of element is digital, but without controller for data transfer.

The recent heat flux meters (HFM) suffer from low performance by weak and constant flows, non-uniformity of the heat flux in the measurement section and impossibility to control the heat flux at different temperatures.

In [22], the authors show a calibration system of a HFM in different operating conditions (low and middle heat fluxes) to design a new prototype with heat flux uniformity and to improve performance in a specific sub-region of the measuring section where the HFM is applied. Furthermore, a metrological characterization of the system allows a combined standard error to be better than 6% at low heat flows. The element is analogue, without controller for data transfer.

In [23] and [24], the authors report heat flow sensors integrated in textile. They determine the amount of heat exchanged between human body and environment. The aim is to improve comfort, efficiency, and sometimes safety of the wearing person. Passive heat flow sensors are used. Such sensors are still under developing and ideas for their appropriate calibration are proposed. Moreover, the existing heat flow sensors are impermeable and do not allow evaporation. This shows less precise results when phenomenon evaporation exists. A flexible heat flow sensor is developed, which is sensitive to water vapor. This sensor takes into consideration phenomenon evaporation and allows better energy measurement during heat exchange. The sensor is analogue without controller for data transfer.

3.3. Sensors for Relative Humidity

Classical devices for relative humidity measurements are psychrometers. Recent research [25] displays indoor air quality and the connected health effects. Complaints about sensory irritation in eyes and upper airways, also perception for dry air are among the most important symptoms in closed areas. In this line sensors for dynamics of particles, bacteria, and viruses in closed areas are necessary for improvement of labour quality and with a sharp focus on absolute humidity impact. The sensors could be analogue or digital and with microcontroller.

In [26], the authors consider a sensor for air humidity measurement using sensitive capacity-dependent crystal. Probe sensitivity is represented too. Moreover, new idea for excitation of entire humidity sensor with stochastic test signals is described, and the humidity measuring method is given. It includes the influence of test signals on weighting function uncertainty and on the A/D-D/A conversion. Error by humidity measurement is lower than 0.2% (t = 15ºC – 25ºC and humidity = 50% – 98%). There is a conversion ADC, DAC in sensor, but it misses a controller.

Research in [27] describes a program, which could simulate simultaneously heat and humidity transfer from walls and plates in closed area and its impact on indoor temperature and humidity. The aim is a sensor development. Recommendation is to be digital and connected to microcontroller.

3.4. Sensors for Illumination

Illumination on basic workplaces and galleries, where the miners move, is obligatory. This is not easy, because the atmosphere in coal mining is often accompanied with methane availability and is highly explosive. Humidity is high, but environment reflectance is extremely low. Therefore, special explosion-proof illuminaters are used and their application is by hardest conditions – low reflection factor, methane availability, high humidity, low and narrow galleries etc.

What are the conditions in ore mining and coal extracting mining? Basically, there are not methane in the first and atmosphere is not explosive. In underground ore mining and these for extracting of non-metalliferous illumination is performed with illuminaters proof from dust and water. In such mining there is no danger from explosion of highly explosive compounds, but they are threatened from fire [5].

For illuminance tracking are applied illuminance meter (luxmeter) and luminance meter.

For measurement in mining galleries are suitable new generation luxmeters “TKA-Lux” (“ТКА-Люкс”) and “TKA-PKM-31” (“ТКА-ПКМ-31”). They have metrological characteristics on the level of the best world manufacturers. The illuminance measurement range is 10 – 200 000 lx, error – 6%.

They have the following performance:

- Viewing angle: 1.0 – 1.5º,

- Range of measurement: 10.0 – 2000 cd/m2,

- Distance to measured object ~ 7m.

Luxmeters with dark scale are applied in coal mining, which is dangerous with gas and dust.

In underground mining exists blindness danger too. Therefore, it is necessary to measure luminance. It is measured with luminance meter. Basic measurement unit is candela [cd]. Recent luminance meter is TKA [5] and [28].

Illuminance assessment in underground mining must obligatory include:

- Illuminance assessment,

- Unevenness assessment,

- Blindness assessment,

- Discomfort assessment.

Special luxmeters are used for illuminance measurement on given surface (workplace). The most widespread luxmeters are photoelectric (objective) luxmeters, consisting of selenium element in series with galvanometer and micro amperemeter. The principle operation of photoelectric luxmeter is conducting a photocurrent between galvanometer`s electrodes by illumination of photoelement. The photocurrent is proportional of illuminance and this dependance could be assumed as linear, when the inner resistance is significant bigger than outer. This ratio is obtained by measurement of small illuminances and application of measurement devices with small inner resistance. The boundary electromotive force of selenium element (0.3 – 0.5 V) is obtained by illuminance 1000 lx and by bigger illuminance it does not change. Therefore, the photoelement illuminance does not have to exceed 1000 lx. For measurement of bigger illuminance is applied an absorbing filter, which decreases X-fold illuminance on photoelement. Selenium element is characterized by its spectral sensitivity too. It is graduated with the help of filament lamp. When an illuminance of other light sources (another light spectrum) is measured it is necessary to use correcting light filters or correcting coefficients, which by naturally illuminance is 0.8, and for luminescent lamps are from 0.88 to 1.2 according to their type [4].

In [29], the author publishes a “Luxmeter, showing light intensity, as it is received from a sensor”.

The listed sensors are analogue and without controller for data transfer.

In [30], the authors show a spectroradiometer as a part of program-instrumental complex for management of illuminance installation in closed areas. Problems of spectroradiometer development are considered. Basic principles for building of automated illuminating system are formulated, based on criteria for quality and quantity assessment of illuminance effect. Scheme of automated illumination complex is considered. New development is represented – spectroradiometer, covering optical irradiation measurement and being a block of system for spectral and energetic management of LED illuminating installations. Attention is paid on the lack of metrological insurance of control of photometric characteristics of energy conservation technology, based on LEDs. It is foreseen that the sensor is digital and has a microcontroller.

3.5. Sensors for Gas Concentration

For measurement of gas concentration portable analyzers are widely used [4]: gas indicating tubes and gas analyzers. From gas analyzers most popular are: Gas Sense – 1000.L.EX; portable device for leakage discovery of explosive gases – Methane (CH4), Propane (C3H8), Butane (C4H10), Liquified Petroleum Gas (LPG), Hydrogen (H2), Ethanol (C2H5OH); Dräger Pac 5500 – measurement of Carbon Monoxide (CO), Hydrogen Sulfide (H2S) or Oxygen (O2); MSA EX-METER II – for measurement in explosive atmosphere; MSA SOLARIS 4 – Four channel gas analyzer, analogue, without microcontroller.

The trend is semiconductor sensors to be doped with metal oxides (e.g., tin) and their application for discovery and protection of environment from different gases like Carbon Monoxide (CO), Carbon Dioxide (CO2), Hydrogen sulfide (H2S), Ammonia (NH3), swamp gas methane, LPG, and many others pollutant gases [31]. Different characteristics of gas sensor in composite form by different temperatures are also displayed. Evidence is produced that sensors in composite form are more resilient than these with a single material. A research about sensor`s output – analogue or digital – is not represented. About its ability for data transfer too.

The author in [32] considers manufacturer methods of zinc oxide nanorods and their application for gas discovery with low concentration due to their various conductance range, reaction of oxidative and reductive gases and extremely high sensitivity and selectivity. A research about sensor output – analogue or digital – is not given. For data transfer ability too.

The survey in [33] describes an electronic gas sensor from nano graphene, which could discover extremely low quantity gas (harmful chemical agents). Nano graphene does not have grainy structure and offers long term stability. Moreover, material has high quality crystal lattice, thus charge carriers move with high velocity and generate low noise. All this supposes design of digital output of the sensor. Due to their specific properties carbon nanomaterials have potential for manufacturing of automated sensors.

The authors in [34] portray high selective gas sensors for smart monitoring and control of air quality, search and save of people etc. Substance choice in complex gas composite is the main challenge. The article represents a guide for material engineering for absorbing, size selecting and catalytical filters. Accent is laid on materials design with purposeful gas separation, portable elements integration and performance. All this shows that gas sensors could be designed with digital output and microcontroller for data transfer.

4. Discussion

The performed short review leads to the findings that the new measurement devices in underground mining are not suitable for automation. Small part of them has a digital output, and most of them are without microcontroller for data transfer. To accelerate and facilitate automation sensors must be delivered with controller. The availability of controller also presumes availability of management services, united in Program Library. The resent achievements are represented with articles with low level detail [35] or high-level concepts [36] and [37]. Other authors go even further away proposing sensors for inspecting of underground mining to be moveable and to be carried from a drone, but without giving detail about their management [38]-[41]. Therefore, Articles for sensors with microcontrollers and management programs must describe comprehensive:

- Integration of sensors and controller;

- Algorithms for management of integrated sensor-controller;

- Function for bearing of sensors for timely reading of fast changing parameters at different places in space aiming sensor security;

- Algorithms for management of sensors bearing, as some

problems are considered: signal propagation; life, size, and safety of battery; security of bearing system etc.

5. Conclusion

Main conclusions from this research are as follows:

- Criteria for assessment of measurement devices in underground mining are synthesized. Methods on which devices perform their functions are specified.

- Devices and measurement units which cover all environmental parameters in underground mining are listed, namely: air temperature; temperature of surrounding building constructions, heated surfaces of technological machines and equipment; heat flow, heat irradiation; relative humidity; velocity of air flow; noise; illumination; gas concentration; dust level; ionizing radiations; radon concentration in air.

- Representations of fast-developing devices are accomplished: for air temperature; for heat flow; for relative humidity; for illumination and for gas concentration. Quality method is used. Assessments organized according to synthesized criteria are defined.

- On the base of discussion about availability of controller to sensor the future work is proposed in following aspects:

- Integration of existing elements sensor and controller and defining of its management;

- Moving of new elements and synthesis of algorithms for its management.

Formulated aim is complex, and this article concentrate on devices` assessment. Representation level and assessments have the necessary depth to illustrate the needed innovations. Basic conclusion from this article is that the developed assessments are eligible base for development of sensors and their management in closed areas, structured as underground mine workings. This will lead to more precise assessment of industrial risk and improvement of safety activities.

Conflict of Interest

The author declares no conflict of interest.

Acknowledgment

This article is a part of project “Survey and Management of Sensors for Microclimate in Mining Galleries” in University of Mining and Geology “St. Ivan Rilski”, Bulgaria.

- M. Ilieva-Obretenova, “Computer System for Microclimate Management in Closed Areas of the Post-Mining Galleries and Greenhouses.” in 7th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE), Ruse, 2020, 1-4, doi: 10.1109/EEAE49144.2020.9278785.

- Ministry of labour and social policy. Healthy Workplaces Campaign, Pictograms 2018-2019, Sofia. (In Bulgarian)

- https://russian.worldbuild365.com/news/nbs9ontsc/hvac/mikroklimat-po-gostu-chto-dolzhen-uchitivat-kazhdyy-proektirovschhik. Accessed June 2021.

- B. Vladkova, ?????????? ???????????, University of Mining and Geology “St. Ivan Rilski” – Sofia, 2020. (In Bulgarian)

- G. Ganchev, ????? ?? ????????????. ??????? ?????????? ? ????? ??????, University of Mining and Geology – Sofia, 2018. (in Bulgarian)

- D. Pressyanov, et al., “Passive radon monitors with part-time sensitivity to radon”. Radiation measurements, 118 (2018) 72-76, doi: 10.1016/j.radmeas.2018.08.014

- H. Mischo, Radioactivity Practical Course. Institute of Mining and Special Civil Engineering. Chair of Underground Mining Methods, Technical University Bergakademie Freiberg, 2018.

- B. Vladkova, ????????? ? ????????? ???????????? – ???????????? ?????????? ? ??????????? ??? ?????? ? ???. University of Mining and Geology, Sofia, 2016. (In Bulgarian)

- Z. Dinchev, ?????? ?? ????????????? ?? ?????????? ??????????. University of Mining and Geology, Sofia, 2016. (in Bulgarian)

- “Wireless Round-the-Clock Observation of Coal Stacks, No Matter where Measurement Points May Move.” 2016, https://www.yokogawa.com/es/library/resources/applicatoin-notes/wireless-round-the-clock-observation-of-coal-stacks-no-matter-where-measurement-points-may-move/.

- Y. Anastasova, “Internet of Things in the mining industry – security technologies in their application.” Sustainable Extraction and Processing of Row Materials Journal, 1, 2020, 7-10, doi: 10.5281/zenodo.4275895

- I. Nikolov, “Development of a warehouse microclimate managing system.” Innovation and entrepreneurship, 6(3), 2018, 166-174

- S. Velinova, S. “Possibilities for using of mining galleries for growing plants on artificial lighting.” International Scientific Conference UNITECH 2017, 148-153

- N. Kolev, Evaluation of main elements of the soil energetic balance by electronic means. Doctor of Science thesis, Sofia, 1996.

- N. Kolev, et al., “Organisation of long-term microcomputer systems evaluation of field water balance elements.” Proceedings of the International Conference Energy efficiency and agricultural engineering, Russe, 2006, 347-353

- Z. Nenova, G. Georgiev, St. Ivanov. “Computer based system for monitoring of the air parametars in the closed premises.” Russe University`s scientific publications, 54(3), 186-190, 2015 (in Bulgarian)

- A. Levi, R. Ivanov, I. Bogdanov, N. Kolev. “Microcomputer systems network for plant growing management – approaches and structure.” Electrotechnica & Electronica (E+E), 2013, 48(7-8), 12-16, doi: 10.1007/s10973-019-08321-6.

- N. Nakayama, K. Misumi H., Koike T. TEMPERATURE SENSOR AND TEMPERATURE SENSOR SYSTEM, United States Patent, Patent No US 8,419,275 B2, Apr. 16, 2013

- C.M. Gerard, Smart temperature sensors and temperature sensor systems, Smart Sensors and MEMs (Second Edition), Woodhead Publishing, 2018, doi: 10.1016/B978-0-08-102055-5.00003-6.

- D. Zhu, C. Koh. TEMPERATURE SENSOR. United States Patent, Patent No US 10,378,969 B2, Aug. 13, 2019

- C.R. Carrigan, TRIAXIAL THERMOPILE ARRAY GEO-HEAT-FLOW SENSOR, PATENT-US-A7516399, 1992, DE92 004606

- G. Cortellessa, et al. “Experimental and numerical analysis in heat flow sensors calibration.” J Therm Anal Calorim 138, 2901 – 2912, 2019. doi: 10.1007/s10973-019-08321-6.

- T.C. Codau, et al., “Embedded textile heat flow sensor characterization and application.” Sensors and Actuators A: Physical, 235, 2015, 131 – 139, doi: 10.1016/j.sna.2015.10.004.

- E. Onofrei, et al., “Textile sensor for heat flow measurement.” Textile Research Journal, 87(2), 165-174, doi: 10.1177/0040517515627167.

- P. Wolkoff, “Indoor air humidity, air quality, and health – An overview.” International Journal of Hygiene and Environmental Health, 221(3), 2018, 376 – 390, doi: 10.1016/j.ijheh.2018.01.015.

- V.D. Matko, “Sensor for high-air-humidity measurement.” in IEEE Transactions on Instrumentation and Measurement, 45(2), 561 – 563, April 1996, doi: 10.1109/19.492787

- M. Transfer, “Dynamik Modelling of Indoor Air Humidity. (PDF) Dynamic Modelling of Indoor Air Humidity (researchgate.net) Accessed April 2021

- G. Ganchev, et al., ?????? ?? ??????????? ? ?????????? ?? ????????? ?? ???????????. University of Mining and Geology – Sofia. 2017. (in Bulgarian)

- C Eng Faruk Bin Poyen. Luxmeter, showing light intensity, as it is received from a sensor. January 2017, (PDF) Luxmeter displaying light intensity as received by sensor (researchgate.net), Accessed April 2021

- S. Baev, “???????????????? ? ??????? ??????????-?????????? ????????? ?????????? ?????????????? ??????????? ? ???????? ??????.” SVETOTEHNIKA, SPECIAL ISSUE, 2019, 55-58, 2019.

- R. Nikam, et al., “Tin Doped Gas Sensors in Semiconductor Metal Oxide Form and Their Scientific Applications: A Review.” J. Biol. Chem. Chron. 2019, 5(3), 53-56, 2019

- Y. Wang, “ZnO Nanorods for Gas Sensors. Nanorods and Nanocomposites. Morteza Sasani Ghamsari and Soumen Dhara, IntechOpen, 2020 DOI: 10.5772/intechopen.85612.

- M. Miandehy, Nano graphen gas sensor (performance and applications). January 2021

- V. Broek, Jan; Weber, Ines C.; Güntner, Andreas T.; Pratsinis, Sotiris E. “Highly selective gas sensing enabled by filters.” Materials Horizons, 8(3), 661-684, 2019, doi: 10.1039/D0MH01453B.

- J. Miller, Proof-of-concept: The day after. Mentor®. A Siemens Business. 2018. www.mentor.com

- W. Ruh, “Drilling Deep into Digital Industrial Transformation will determine who survives and thrives.” – Internet of Things Magazine, September 2018.

- C. Perera, et al., “Designing the Sensing as a Service Ecosystem for the Internet of Things.” – Internet of Things Magazine, December 2018, 1, 2.

- R. Gonzalez, et al., “Navigation technics for mobil robots in greenhouses.” Applied Engineering in Agriculture. 2009, Vol. 25, No. 2, pp. 153-165

- roboticsbiz.com. Drones in underground mines – Applications and benefits, Drones in underground mines – Applications and benefits (roboticsbiz.com) September 28 2020, Accessed April 2021

- J. Shahmoradi, et al., “A Comprehensive Review of Applications of Drone Technology in the Mining Industry.” Drones. 2020. 4. DOI: 10.3390/drones4030034.

- University of Utah. A Safer Battery to Power Drones in Underground Mines. A Safer Battery to Power Drones in Underground Mines | Technology Org, April 9, 2021