Redesign and Improvement in the Management of the Raw Material Inventory Control Process with Oracle APEX

Volume 7, Issue 6, Page No 103-113, 2022

Author’s Name: Jhoys Alinson Delgado Delgado, José Sulla-Torresa)

View Affiliations

Universidad Católica de Santa María, Escuela de Ingeniería de Sistemas, Arequipa, 04000, Perú

a)whom correspondence should be addressed. E-mail: jsullato@ucsm.edu.pe

Adv. Sci. Technol. Eng. Syst. J. 7(6), 103-113 (2022); ![]() DOI: 10.25046/aj070611

DOI: 10.25046/aj070611

Keywords: Inventory, Raw material, Process management, Textile company, Redesign, Framework, Scrum, Oracle Application Express

Export Citations

Having reasonable inventory control is a priority for any company because a lack of inventory could incur economic losses. Not having the necessary stock for the timely production of your orders could generate dissatisfaction in your customers and possibly cause them to lose them. Likewise, reasonable inventory control allows quick decision-making for the company’s benefit. The study’s objective was to improve the management of the request process, and quality control of the raw material of a textile supplier exporter of Peruvian alpaca yarn and an exporter of the textile company focused on transforming alpaca fiber and other natural fibers into high-value-added products. It was redesigned under the Process Management approach, developing and implementing software to control raw materials and requests following the Scrum framework and using the Oracle Apex tool. The results obtained with the new system were very positive, increasing workers’ productivity, eliminating manual tasks and calculations, avoiding confusion in the allocation of material to scheduled orders, and the response time of the delivery date of orders and, therefore, customer satisfaction. Concluding that, it was possible to lower from an initial 30% to 0.08% of the requests answered in a period greater than 48 hours with the application of the developed system that allows rapid decision-making.

Received: 19 September 2022, Accepted: 12 November 2022, Published Online: 26 November 2022

1. Introduction

The quality control of the raw material is one of the most critical issues in the manufacturing process of products with the advancement of technology [1]. To meet the high technical requirements, effective quality control at the initial stage of raw material can significantly reduce the quality risk during the manufacturing process [2].

This problem is not unrelated to the textile industry [3]; one of the most important companies in the textile industry, a supplier of Peruvian alpaca yarn and internationally recognized for its fine quality products, in one of its critical processes for handling orders: the control and request of raw material, this process is obsolete and takes a long time (hours/worker) to be able to carry it out correctly, for this reason, said control is reviewed once a week, and on certain occasions depending on the urgency, it is it can review up to three times maximum, also generating a delay in the other activities of the worker, which is critical for the company since it strictly depends on the availability of raw material to be able to produce and deliver its orders on time.

On the other hand, inventory management represents a key factor within any organization. A company’s poor inventory management practices influence its productivity, leading to raw material shortages, production delays, rework, and material loss [4].

For this reason, the research seeks to satisfy the need of a textile company to improve its control process and raw material request to achieve better productivity [5] in its workers, keeping the information updated and available for decision-making and high command decisions. The contribution and novelty of the work is to analyze and redesign the process under the Process Management approach, to develop and implement software that adapts to the new process flow, following the agile Scrum framework and using the Oracle APEX tool.

The new flow of the process will seek to: improve the response time to requests for the delivery date of new orders to avoid loss of sales due to a slow response to requests or avoid delays in the delivery of orders, also contributing to an improvement in the level of customer satisfaction. Likewise, it will seek to avoid errors in allocating material for scheduled orders, increase the productivity of the users involved in the process, and speed up decision-making when dealing with orders.

2. Related Work

Inventory control in an industrial company has become a critical process since inventories represent a considerable investment on the company’s part. Their absence generates delays in order delivery dates, loss of sales or customers, and economic losses.

According to [6], reasonable inventory control allows one to have a broad knowledge of the rotation of the products and, based on that, to be able to make purchasing decisions; where they indicate that the benefits of an Inventory Control System are a better cash flow in the company, improvement of the quality indicator of customer service, customer loyalty, recognizing products with little demand, higher inventory turnover, theft detection and optimized space in warehouses.

Comprehensive inventory management is critical to efficiently operating any facility that uses and stores products. Since today’s technologies are essential to support all processes within a company, In [7], the author indicates the benefits of having inventory management software. Most of the inventory management software available in the market focuses on regulation or acquisition and usually comes with monthly or upfront fees.

To use technologies as a support tool, it is first necessary to have a well-defined process that will be automated; for this, there is Process Management. Today is critical for any organization since processes are the heart of it; automating, optimizing, or redesigning these processes saves time and money, representing a notable competitive advantage over any other organization.

In [8], the author mention that Purpose Comprehensive management systems, such as ISO 9001 or ISO 14001, are designed to help organizations improve processes, ensure customer satisfaction, efficient information flow, efficient use of resources, and many other thriving management areas. These systems can also have unintended direct and indirect effects on organizations.

Once the process is well defined, it is proceeded to automate with software that suits the needs of the same and the users; given the complexity of the type of business of the company in question and the size of it would be much more efficient and effective if the software is custom developed. Today there are different methodologies for implementing this, which support us when performing this task. Like any organization, the most sought-after is a straightforward methodology to understand and, above all, very efficient, such as the well-known Agile Methodologies. In [9], the author indicates that since the agile manifesto was created in 2001, the research community has paid much attention to agile software development.

Specifically, they delineate the conceptual framework underlying agile scholarship by analyzing authors who have made notable contributions to the field. Agile methodologies are born from the need to respond rapidly to change to increase customer satisfaction by delivering operational functionality and continuous feedback to the customer during the project.

Nowadays, using these methodologies is essential since they help reduce the project’s completion time because everything would already be very well organized, and the tasks would already be ordered by priority. These methodologies help to have an exact idea of what is being done at any point in its development and, in turn, encourage constant communication between the project members so that the result is successful.

In [10], the author state that to optimize and improve processes, in most cases, information systems have been developed using traditional methodologies that have fulfilled their function over time but that, however, have a lower probability of success. Not meeting all the needs of the client because the requirements may have changed, and these changes cannot be alerted or validated at the end of the project. The same authors refer to the fact that agile methodologies show promising results in projects that present constant changes in the definition of their requirements due to the different business environments; the agile team works much better from the moment they understand that a product that gives value to the client, and therefore they will have to consider that after each review with the client and after the development of each deliverable, changes could be requested. They also mention that agile teams are self-organized and multidisciplinary since they can develop their skills, knowledge, and experience, which means the same level of responsibilities for the entire team; It should also be noted that constant communication allows the team to make timely decisions.

Likewise, in the study [11], work points out that software development depends significantly on team performance, as does any process involved. According to [12] point out that within the Peruvian economy, there are critical business sectors, such as mining, mainly because their products are in great demand as essential components used by other industries, such as construction, mining, and textiles, which includes evaluating productivity in terms of growth rates and levels. They use Lean Manufacturing tools to measure these indicators and propose improvements or solutions to generate added value for the company.

In addition, the work of [13] indicates that in Peru, many small and medium-sized companies (SMEs) do not have a system focused on Human Resources because companies do not have the necessary technology to implement it, they do not know it, or the prices are pretty high. That is why they designed a payroll control and monitoring system based on the Agile Scrum Methodology, taking as an example the textile company Chalicen S.A.C, which is within the range of small companies.

On the other hand, Oracle Apex has become an exciting tool for developing effective and efficient applications. In [14], the author presented a technology solution integrating Oracle Apex and Python development software, where open-source libraries powered by Python provide an approach to Big Data analysis. On the other hand, the powerful database management offered by Oracle, powered by Apex application creation software, requires the cooperative use of such intellectual processing tools. Similar work on inventory management software developed with Apex was presented in [15].

Given the references, we will seek to redesign the current raw material control and request process based on process management and, in turn, develop and implement software based on the Scrum framework. This software should cover the company’s needs to improve the time hours/worker, keeping the information in real-time and available for any decision-making of the high command. It should be noted that it will be developed under the Oracle Apex tool.

3. Material And Method

The analysis of the process will be carried out with the following activities.

3.1. Description of the Company

The textile company under study is classified as a macro-company. It is one of the most important companies within the exporting suppliers of Peruvian alpaca yarn, internationally recognized for its fine quality products. It is worth mentioning that it is also one of the pioneer companies worldwide in offering 100% certified organic alpaca.

According to its vision and mission, this company aims to transform alpaca fiber and other natural fibers into products with high added value, satisfying the world’s needs, promoting its use globally, and caring for the community and the environment. It aims to be the world leader in providing warmth and shelter with the best alpaca and natural fiber products. It offers unique experiences to our customers and community sustainably and innovatively through a committed and empowered team.

In Figure 1, its traceability circle is shown; it begins with the raising of alpacas on its farm, then it goes through a fiber treatment, and finally, it goes through the spinning of these. They have industrial processes of washing, carding, combing, spinning, dyeing, and weaving, ending in the dispatch of the product.

Figure 1: Traceability of the textile company

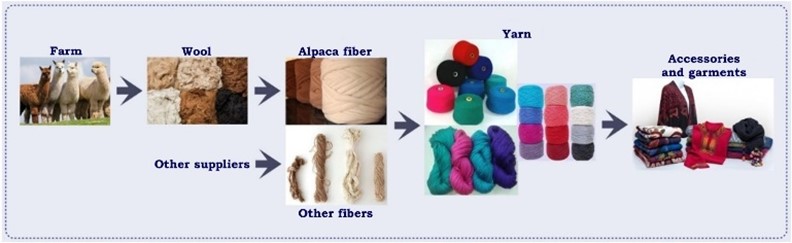

Figure 2 shows the dynamics of the company: the alpacas raised on the farm go through a shearing process to extract their wool, which goes through a treatment process, thus becoming Alpaca fiber Tops; mention that the company not only uses fibers extracted from the farm but also works with other fibers such as sheep, silk, cotton, nylon, linen, among others, which are acquired from other national or international suppliers, these fibers are mixed between yes, according to the percentages requested by the client through the spinning processes, obtaining three yarn presentations: yarn for machine weaving in cones and skeins and yarn for hand weaving in balls and skeins, they also offer accessories and garments made of fabric knit and flat knit.

Figure 2: Dynamics of the textile company.

3.2. Process Discovery

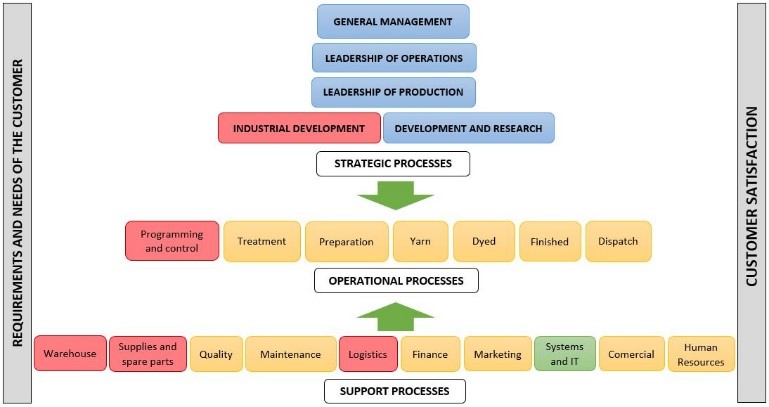

Within the three disciplines of value: product leadership, operational excellence, and intimacy with the client, the value proposition of the company in question are based on the discipline “Product Leadership,” which is this: supply the best product menu diversified in terms of quality, fineness, and color of alpaca fiber to the world, through systems, efficient processes and committed personnel that is capable of providing the best service; according to this, Figure 3 shows the process map, since the problem occurs in the current process of Control and Request for Raw Material, the areas involved have been highlighted: Programming and Control, Industrial Development, Warehouse, Inputs and Parts, and Logistics.

Figure 3: Process map of the textile company.

The process map of the textile company under study is presented, highlighting the processes involved in the investigation in red color.

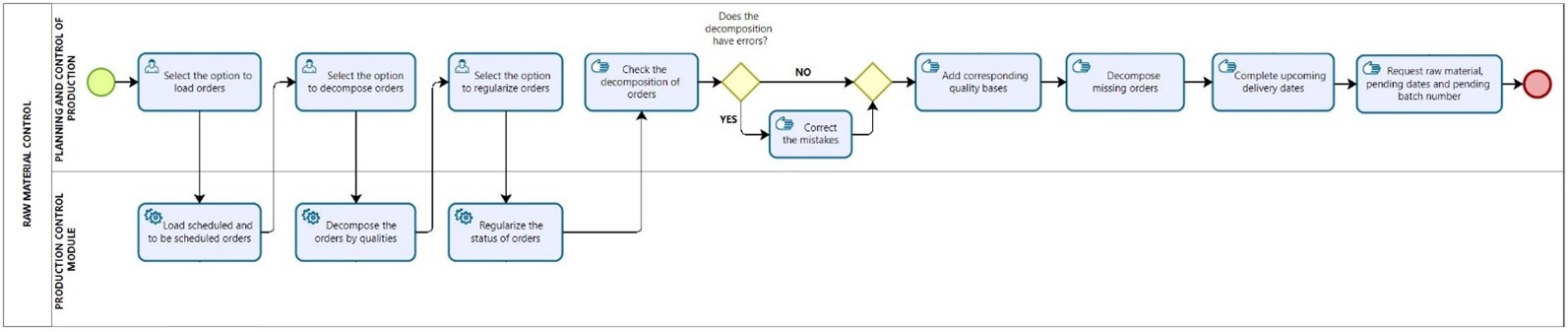

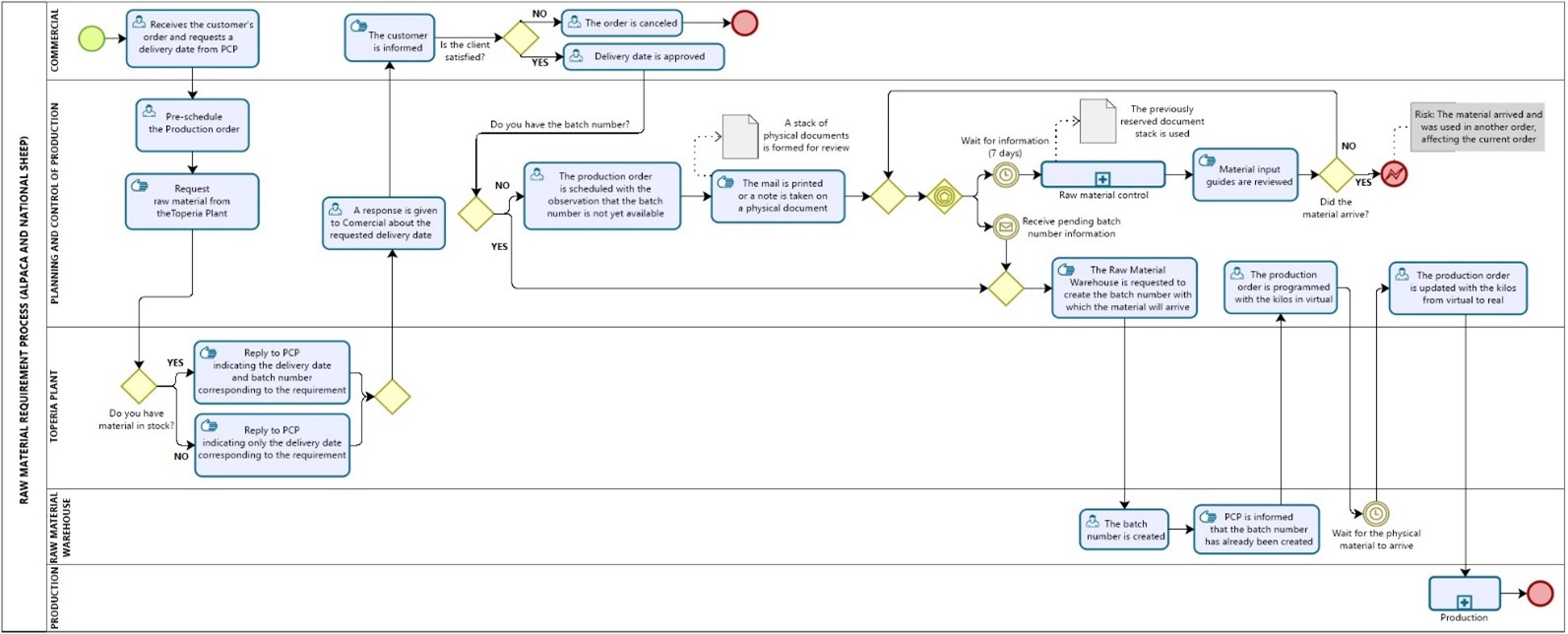

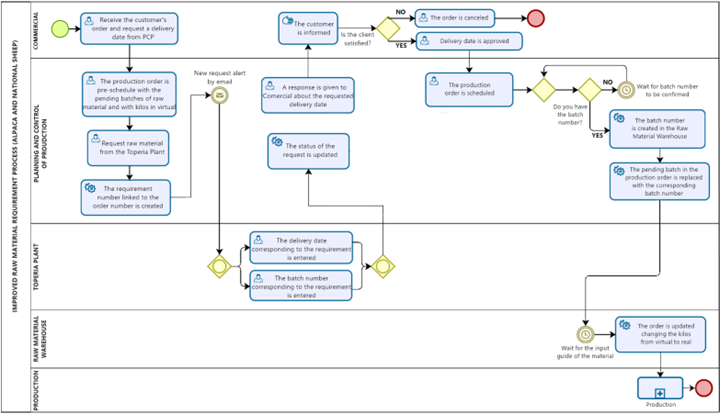

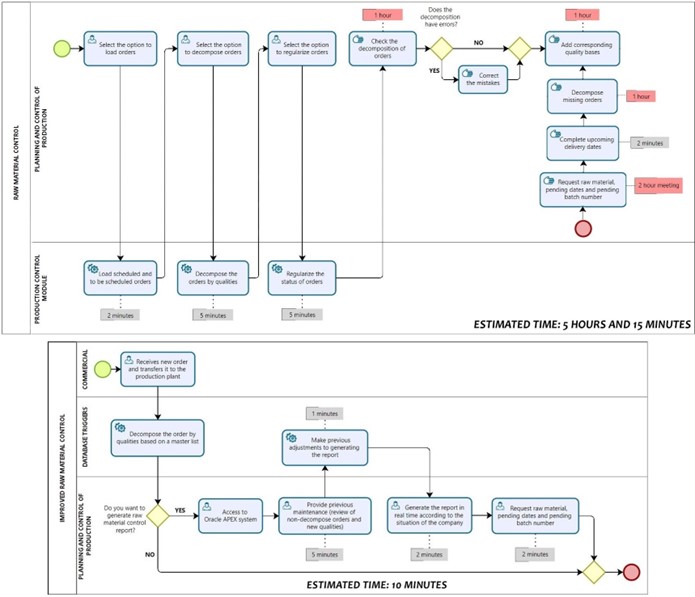

- Initial process model: With the Bizagi tool’s help, the initial raw material control process diagram is presented, referring to scheduled and pending orders or to be scheduled. Figure 4 shows the graph of the initial process of raw material control. Figure 5 shows the initial process of requesting raw materials for alpaca and national sheep.

In the general process of raw material control, where the following waste is observed:

- Overprocessing: By breaking down all the orders again each time the information is required, the correct thing would be to store a history of previously made breakdowns.

- Defects: As the order breakdown process is not well defined, the end of the data generation presents errors or shortcomings that must be corrected or added manually by the user.

- Waiting: It is evident that there is a very high waiting time since it is impossible to make any decision without the data generated from the said process.

Figure 4: Diagram of the initial raw material control process.

Figure 5: Diagram of the initial process for requesting raw material for alpaca and national sheep.

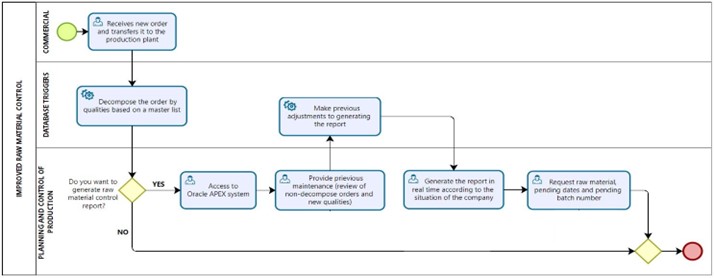

Figure 6: Diagram of the improved raw material control process.

Then there is the process of requesting raw material for alpaca and national sheep, where the following waste is observed:

- Overprocessing: By constantly modifying the production order, generating a stack of physical documents to control the delivery of the material, and requesting the creation of the batch number.

- Defects: By having an inefficient process, there is confusion with the material’s assignment to the scheduled orders, causing their delay.

- Waits: The most significant delay occurs when waiting for the confirmation of the batch number to finish programming the production order.

In both raw material request processes, it is evident that there is a more common waste, and that is the waste of human talent, by outsourcing activities.

3.3. Process Redesign

An improved raw material control process is carried out regarding scheduled and pending orders or orders to be scheduled. Figure 6 shows the diagram of the improved raw material control process. Figure 7 shows the enhanced process for requesting raw materials for alpaca fiber and national sheep.

The new raw material control process begins when a new order is entered in the Commercial area and is transferred to the Programming and Production Control area in the request of a delivery date, automatically entering decomposition by the system with the help of a defined Master of Qualities and bases, in this way when the user requires it, he will already have the stored information of the decomposition of all the orders.

Before generating the report, a prior review should be given to see if any order was partially decomposed or if one was not since a new quality may have been created in some order, which has not yet been considered in the Master of Qualities and bases. The user must add the unique quality to the master; once added, the system will automatically decompose all the pending orders that contain this new quality.

Once the report is generated, there should be complete information on all breakdowns and the stock of raw materials: stock in a warehouse, stock in production, supply in request, and missing stock; with this information, the user will be able to make decisions quickly.

3.4. System Development with Scrum and Oracle Apex

The agile Scrum methodology [16] will be used to construct the software. The Scrum guide was recently updated by its authors Ken Schwaber and Jeff Sutherland in November 2020, making it intelligible since they decided to reduce the prescriptive language and point to a general language applicable to different areas and not only to technology areas; It is also highlighted that the guide shows how essential it must be to implement it; however, it is possible to complement it with other processes, techniques, and methods [17].

Given the need of the company in question and the characteristics of the process analyzed, it is decided to take the strategy of division by process flow, thus leaving a division of five Sprints ordered by priority based on the collected user stories.

Within the five sprints, the following non-functional requirements will be taken into consideration: a) System accessibility, b) System portability, c) Friendly user interface, d) Reliable information, e) System scalability, f) System flexibility, and g) Can be integrated into the current system.

Figure 7: Diagram of the improved process for requesting raw material for alpaca and national sheep.

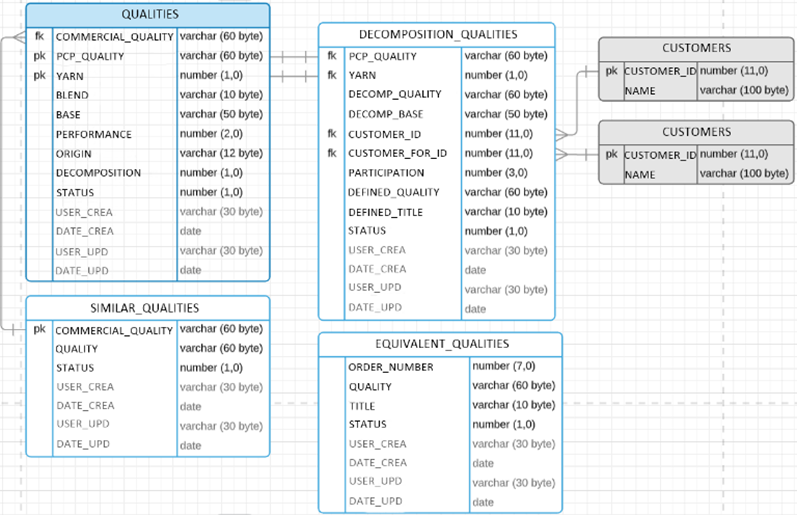

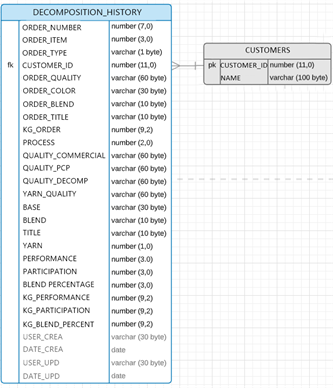

- Data Model: Figure 8 shows the data model of the base tables for the Master of Qualities, where the names of the fields are observed together with the type of data, data length, and the relationships between the tables.

Figure 8: The master relational model of qualities.

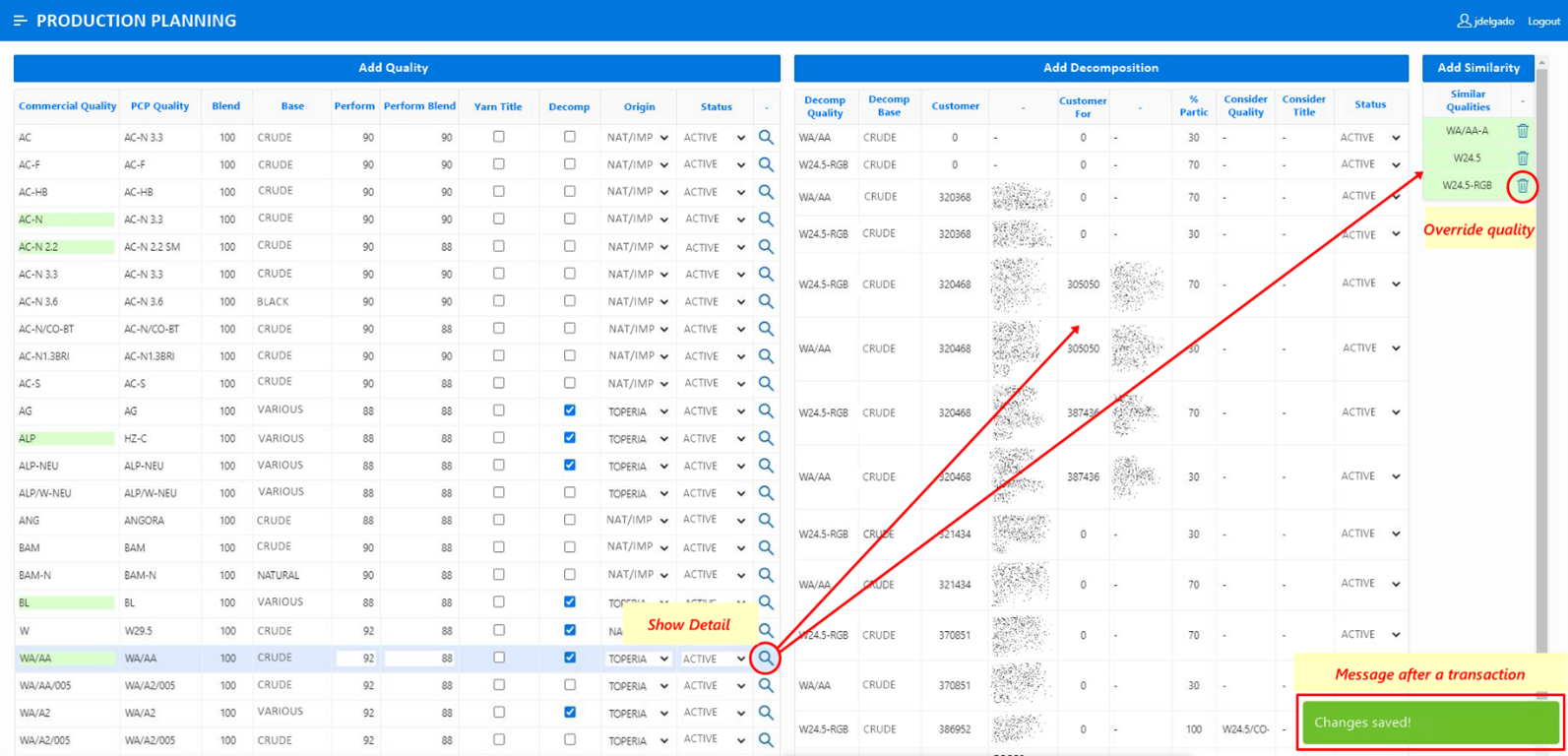

- Oracle APEX: Oracle APEX, being a low-code graphical tool, as mentioned by Baggia1, Leskovar, and Rodič [18], allows us to prototype while it is being developed, representing significant time savings in the development of the project. These pre-prototyped interfaces can be adjusted or modified in a matter of minutes, which fits with the Scrum framework regarding the adoption of changes by the customer.

Before starting with the development documentation, it should be clarified that the project was led and developed by the same person due to the mechanics of the Systems and IT area in the textile company.

When entering the interface of the master of qualities shown in Figure 9, three columns will be observed: the first shows the header of the master, the second that shows the detail of the decomposition of qualities, and the third where the similar attributes will be registered; All the related information will be displayed from the header, selecting the magnifying glass icon, the rate will be painted green when it has similar qualities registered.

Figure 10 shows the deliverable of the data model of the table that will store the history of the decompositions of the orders transferred to the plant; from this history, it is that the summary report of the raw material can be generated for correct control.

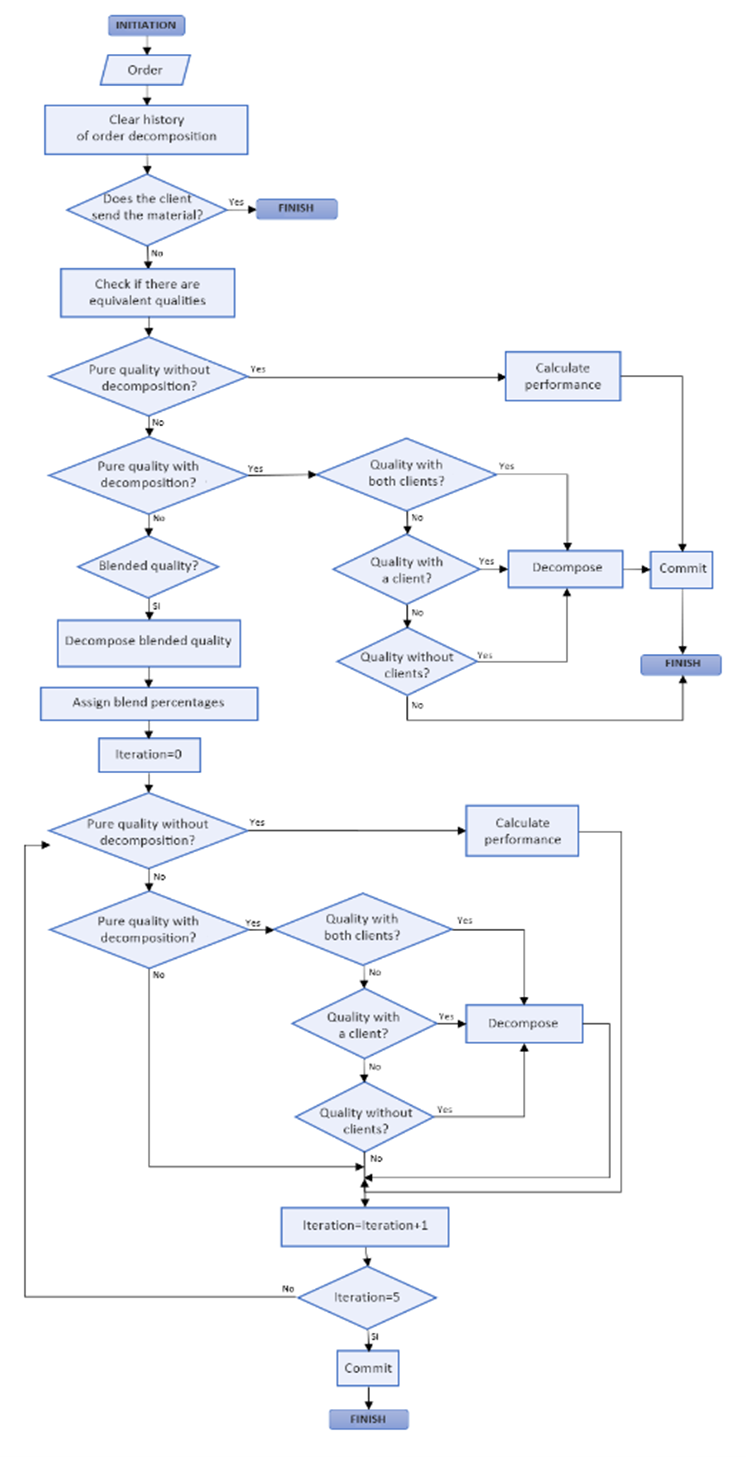

- Iterative algorithm: As part of the second deliverable, the quality decomposition procedure is presented; this will start when there is a transfer of an order from the commercial area to the plant; the order will automatically enter decomposition and will generate the information that will be stored in the decomposition history table. Figure 11 defines the algorithm that was developed to decompose the orders.

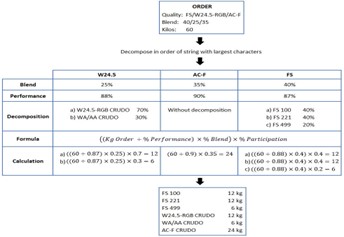

To better understand the decomposition of qualities, a practical case of the decomposition of an order is shown in Figure 12. The order is entered with three mandatory data: the rate, the mixture, and the number of kilos requested. In this case, the order is entered with mixed quality, and the mixed data corresponds to the percentage of participation of each pure quality identified in the mixed quality. The first step would be to break down the mixed quality into its pure qualities according to the order of the chain with the highest number of characters, with the pure quality W24.5 being found first, then AC-F, and finally FS. For each pure grade, its blend % is assigned according to the blend data received in the order; then, the grade is searched for in the graded master, assigning its yield % and identifying if the grade has decomposition. If the quality has decomposition, a % of participation must also be given for each component. Finally, the calculation is made according to the established formula, thus obtaining all the details of the order.

Figure 9: Oracle APEX interface of the quality master.

Figure 10: Entity relationship history model of quality decomposition.

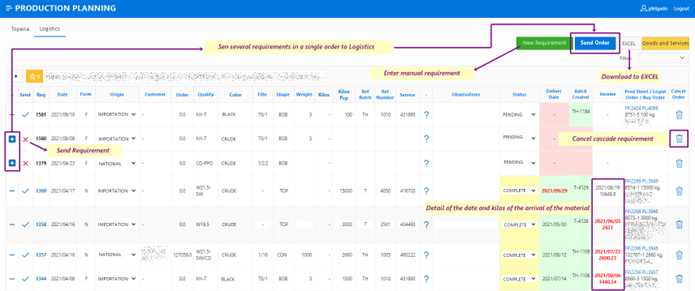

The logistics raw material requirements interface shown in Figure 13 is like the Topería requirements interface because it also has editable fields and an option to send the requirement. Still, it is handled in a different way distinct.

This interface can send several requests in a single order to Logistics and cancel the request in a cascade. The fields title, weight, kilos required, reference batch type, and good service code must be filled in before sending the request. In the same way as the interface to Topería, there is the option to download the information to excel, create a manual submission, and display the date and kilos of the material entered.

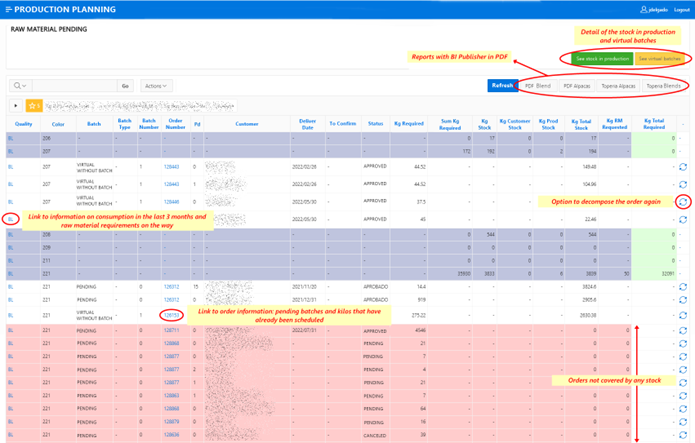

Figure 14 shows the interface of the raw material referring to the Top type qualities. Links have been added in the QUALITY and ORDER fields to access detailed information. Similarly, in the upper right part of the interface, a couple of buttons were added to access the information on the stock in production and the lots with virtual kilos. Below these information buttons are links to report downloads. in PDF formats. A region is highlighted in red; this indicator will alert the user that these orders are not covered by the existing stock or any raw material requirement. You can break down an order again if the user requires it

4. Results

4.1. Analysis of the Average Time of the General Process

The average time it would take to execute the general Raw Material Control process was analyzed as part of the system evaluation. Figure 15 shows that the previous process took approximately 3 hours and 15 minutes, plus 2 hours for a coordination meeting between the different areas of interest. Whereas, with the new approach, it takes 10 minutes to control raw material correctly.

Figure 11: Flowchart of the iterative algorithm of the quality decomposition.

Figure 12: A case study of the decomposition of an order.

Figure 13: Time analysis of the Raw Material Control process.

Figure 14: Time analysis of the Raw Material Control process.

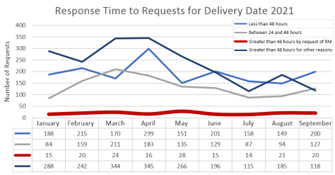

4.2. Analysis of Response Time to Delivery Date Requests

In analyzing the process problems, the indicator of response time to delivery date requests was implemented, which classifies why the response exceeds 48 hours. In 2020, it was found that approximately 31% of the proposals that exceeded the 48-hour response time were due to a pending raw material request.

Figure 16 shows the analysis of the response time so far in the year 2021; the level of response exceeding 48 hours per raw material request seems to have decreased.

Figure 15: Time analysis of the Raw Material Control process.

Figure 16: Response time to delivery date requests.

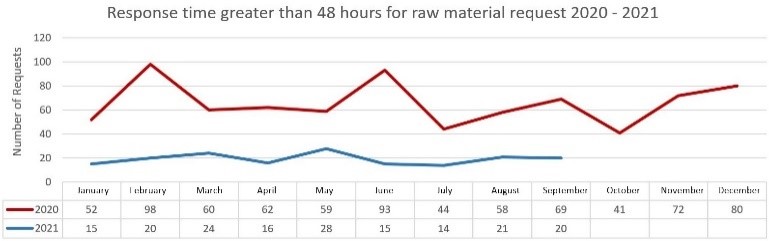

In Figure 17, we compare the values for 2020 against those obtained for 2021 concerning the response time for raw material requests exceeding 48 hours. It is confirmed that the percentage was considerably reduced from 30% to 0.08% of requests answered over 48 hours. With this, we can say that the objective of improving the response time for delivery date requests has been met.

Figure 17: Comparison of response time per raw material request 2020-2021.

5. Discussion

Our results show that with the developed system, we obtained a considerable reduction in the execution time of the process; likewise, we were able to reduce from an initial 30% to 0.08% of the requests answered in a period longer than 48 hours, in addition to eliminating different tasks and manual calculations such as the calculation of yields, manual control of the number of lots in the warehouse, decomposition of yarn qualities, among others. It was also possible to avoid confusion in assigning material to programmed orders. Likewise, the control and the raw material process were successfully optimized by redesigning its flow, developing a system in Oracle APEX, and implementing it through the SCRUM methodology.

These results coincide with those of [4]. They demonstrate that implementing the management model in the textile company in their study can increase effective operational productivity from 82.61% in the current system to 130.43% in the proposed approach. Similarly, a reduction in the rate of defective products from 20.83% to 6.25% is identified. Finally, 100% compliance with scheduled deliveries was achieved; in other words, the order was delivered within the agreed time. Likewise, it coincides with the importance of analyzing the inventory life cycle in textile equipment and its evaluation using the software as input data, among others, the raw material [19].

Through the analysis of the operation of the raw material control and request process of the textile company, the main flows were identified, as well as their critical points: Raw material control, raw material request (alpaca and domestic sheep), and raw material request (imported sheep and yarn).

Under the Process Management approach, it was possible to redesign the raw material control and request process, eliminating the identified wastes of over processes, defects, and waiting times in the process flows.

Using the Scrum methodology, we were able to meet the needs of the users and the textile company: (i) improve the response time to delivery date requests, (ii) avoid the loss of sales due to a slow response to requests, (iii) avoid errors in the allocation of material in scheduled orders, (iv) avoid delays in the delivery of orders, (v) improve the level of customer satisfaction, (vi) increase the productivity of the users involved and finally (vii) facilitate rapid decision making.

The software necessary for the new flow of the raw material control and request process was developed and implemented, proving that the tool used (Oracle APEX) allows the development of basic applications, as well as much more advanced applications, which makes its use possible in small, medium, and large companies. This coincides with the work of [20], where Oracle Apex facilitates the creation of secure and scalable applications with outstanding features. Likewise, comparing it with other works that showed the benefits of using Oracle Apex as in [21] where the use of the APEX Oracle platform for the development of their application and analysis of the data set gave them a data accuracy of 78% compared to any other existing technique, which is similar to the results achieved in the present study. Other studies highlight the benefits of using Oracle APEX as [22] and [23].

6. Conclusions

The study has covered the process of controlling and requesting raw materials from a textile company in Arequipa-Peru.

After the implementation of the proposed system, the main result was a considerable reduction in the execution time of the process; likewise, it was possible to lower from an initial 30% to 0.08% the requests answered in a period greater than 48 hours, In addition, different tasks and manual calculations were eliminated, such as the calculation of yields, manual control of the number of batches in the warehouse, decomposition of yarn qualities, among others. Confusion in assigning material to scheduled orders was also avoided.

It can be concluded that the implementation of the new raw material control and request process flow was successful and facilitated the work of the users involved; likewise, the new flow improves the response time to delivery date requests.

For future work, it is recommended to carry out a continuous improvement cycle in all the company’s processes, under the Process Management approach, in order to ensure the quality of its systems and obtain growth opportunities. Likewise, applying the same raw material request procedure in the Research and Development area is proposed since it would be the only link not considered in the analyzed flow. From this area, raw material requests are made with a few kilos because they are used for testing new fabrics; however, it is essential to account for these raw material revenues.

Conflict of Interest

The authors declare no conflict of interest.

- V.S. Guan, J. Shui, K. Chang, “The quality control application for abnormal raw material early detection,” in IEEE International Conference on Industrial Engineering and Engineering Management, 2014, doi:10.1109/IEEM.2013.6962597.

- X. Shui, A. Shangguan, Y. Yu, H. Gao, “Advanced quality control at raw material kickoff stage,” in IEEE International Conference on Industrial Engineering and Engineering Management, 2016, doi:10.1109/IEEM.2015.7385788.

- A.R. Guevara-Yarasca, G.F. Falla-Marcelo, J.C. Quiroz-Flores, J.C. Alvarez-Merino, “Supply Model for Dependent Demand in the Peruvian Textile Industry: A Case Study,” in IEEE International Conference on Industrial Engineering and Engineering Management, 2019, doi:10.1109/IEEM44572.2019.8978862.

- K. Argumedo-Gonzales, A. Pumahuare-Ayala, E. Aparicio-Lora, E. Altamirano-Flores, C. Nunura-Nunura, “Proposal to Improve the Inventory Management Model in a Textil SME based on the Plan for Every Part,” in Proceedings of the LACCEI international Multi-conference for Engineering, Education and Technology, 2021, doi:10.18687/LACCEI2021.1.1.498.

- A. Kumbara, A. Hariadi DP, “Expanded the Production Effectiveness Through Production Planning, Raw Material Control, Schedule Control And Production Control AT PT. LPA,” Dinasti International Journal of Education Management And Social Science, 2(5), 2021, doi:10.31933/dijemss.v2i5.945.

- C.A. Quinde Espinoza, T.K. Ramos Alvarado, “Valuación y Control Del Inventario y Su Efecto En La Rentabilidad,” Revista Observatorio de La Economía Latinoamericana, 0(0), 2018.

- M.K. Payne, A.W. Nelson, W.R. Humphrey, C.M. Straut, “The Chemical Management System (CMS): A Useful Tool for Inventory Management,” Journal of Chemical Education, 97(7), 2020, doi:10.1021/acs.jchemed.9b00905.

- D. Zimon, P. Madzík, S. Dellana, R. Sroufe, M. Ikram, K. Lysenko-Ryba, “Environmental effects of ISO 9001 and ISO 14001 management system implementation in SSCM,” TQM Journal, 34(3), 2022, doi:10.1108/TQM-01-2021-0025.

- T. Dingsøyr, S. Nerur, V. Balijepally, N.B. Moe, A decade of agile methodologies: Towards explaining agile software development, Journal of Systems and Software, 85(6), 2012, doi:10.1016/j.jss.2012.02.033.

- L.M. I., V.A. M., “Hybrid method for agile software develop mobile devices [Método ágil híbrido para desarrollar software en dispositivos móviles],” Ingeniare, 23(3), 2015.

- N.B. Moe, T. Dingsøyr, T. Dybå, “A teamwork model for understanding an agile team: A case study of a Scrum project,” Information and Software Technology, 52(5), 2010, doi:10.1016/j.infsof.2009.11.004.

- J. Cruz-Rojas, R. Rojas-Villa, F. Maradiegue, C. Raymundo, Lean Production Management Model Using an Agile Approach Applied to Increase Productivity in Small and Medium-Sized Chemical, Education Excellence And Innovation Management: A 2025 Vision To Sustain Economic Development During Global Challenges, 6354–6363, 2022.

- A. Delgado, “Web System Design for Human Resources Management in an SME in the Textile Sector,” International Journal of Emerging Trends in Engineering Research, 8(4), 2020, doi:10.30534/ijeter/2020/87842020.

- V.N. Timokhin, N. V Timokhin, A.N. Medvedev, “Big data analysis with Python and Oracle APEX integration,” in AIP Conference Proceedings, 110029, 2022.

- J.D. Patiño Parra, A.K. Acosta Quintero, J.A. Ramirez Morales, juan.patinop@campusucc.edu.co, angie.acostaq@campusucc.edu.co, jorgea.ramirezm@campusucc.edu.co, “Software para la gestión de inventarios desarrollado con apex (Oracle Application Express),” M. BV Álvarez. Modelos Económicos Matemáticos II. La Habana: Editorial Félix Varela., 2006, Pp.15., 2019.

- K. Schwaber, SCRUM Development Process, 117–134, 1997, doi:10.1007/978-1-4471-0947-1_11.

- K. Schwaber, J. Sutherland, The scrum guide the definitive guide to scrum: The rules of the game, 2020.

- A. Baggia, R. Leskovar, B. Rodič, “Low code programming with oracle APEX offers new opportunities in higher education.,” ITEMA, 2019, doi:10.31410/ITEMA.S.P.2019.91.

- R.M. Aileni, R.I. Radulescu, L. Chiriac, L. Surdu, “Life cycle assessment of the electroconductive textiles functionalized by advanced technologies (plasma) and metallic micro/nanoparticles deposition,” Industria Textila, 70(3), 2019, doi:10.35530/IT.070.03.1476.

- K. Talesra, N. G. S., “Low-Code Platform for Application Development,” International Journal of Applied Engineering Research, 16(5), 2021, doi:10.37622/ijaer/16.5.2021.346-351.

- V. Pathania, S.Z.D. Babu, S. Ahamad, P. Thilakavathy, A. Gupta, M.B. Alazzam, D. Pandey, A Database Application of Monitoring COVID-19 in India, Springer: 267–274, 2023.

- S. Farshidi, S. Jansen, S. Fortuin, “Model-driven development platform selection: four industry case studies,” Software and Systems Modeling, 20(5), 2021, doi:10.1007/s10270-020-00855-w.

- E. Bašić, Organizacija vjenčanja-poslovna aplikacija nad relacijskom bazom podataka (Oracle APEX), University of Rijeka. Department of Informatics, 2021.